20

November

When it comes to the installation and maintenance of LED displays, your number one priority is always reliability, visual quality, and smooth operation. Whether the LED display is lighting up a retail store, driving a mission-critical operation center, or catching the eye in a busy city square, the way you maintain your LED display impacts everything from performance and aesthetics to long-term cost.

Both front service and rear service are proven approaches for keeping your LED screens up and running. But which one is truly best for your needs? This is a common question for both newcomers and seasoned industry professionals alike.

In this article, I go in-depth into the “Front Service vs. Rear Service” debate. You’ll get a clear understanding of what each method offers, their differences, and practical tips on how to choose the best fit for your LED project-so you can make an informed decision for your display’s long-term success.

Ready to get started? Let’s dive in.

In This Article

Introduction

What is front service?

What is rear service?

The Difference Between Front Service and Rear Service

The Pros and Cons of Front Service and Rear Service

How to Choose the Right Maintenance Method for Your LED Display

Conclusion

Introduction

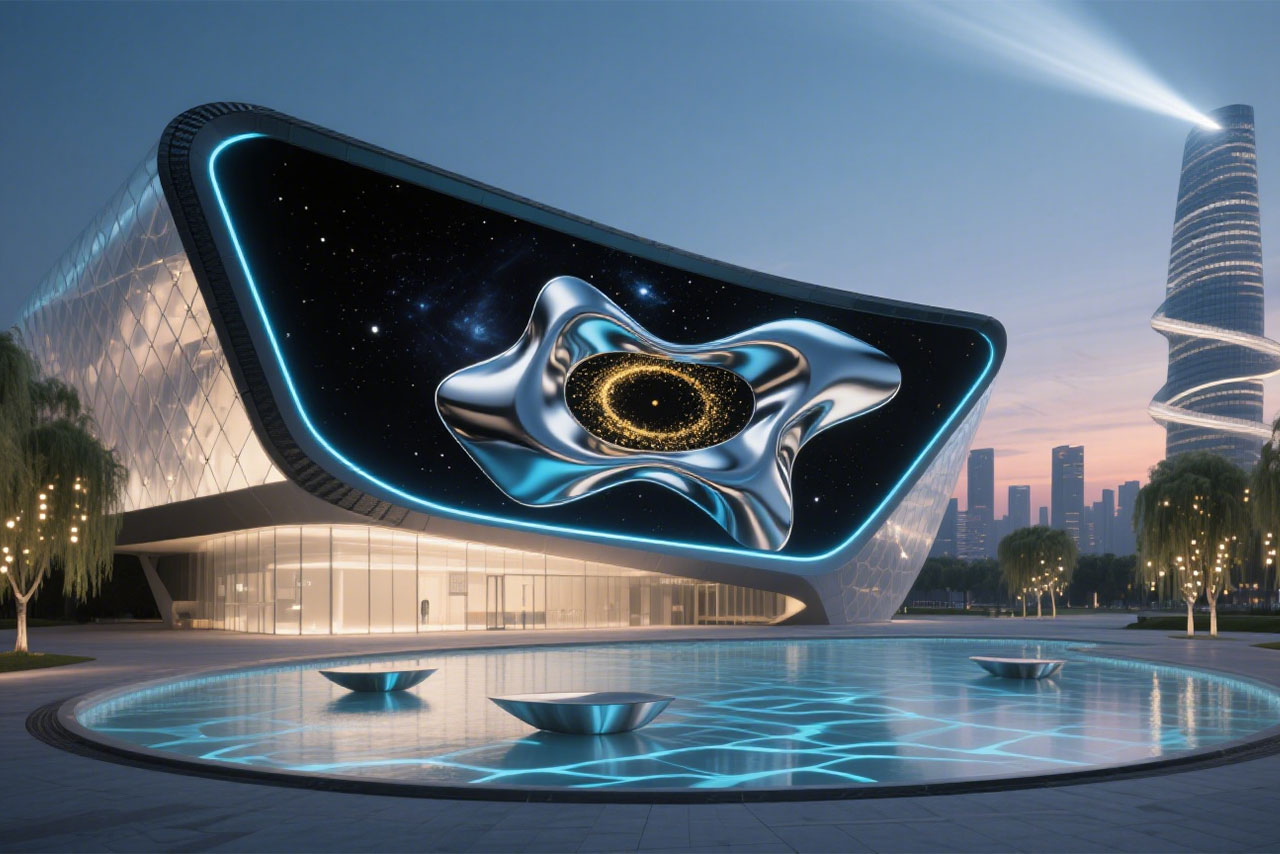

LED displays have become the visual heartbeat of our built environment, from colossal outdoor billboards crowning city skylines to sleek wall-flush lobby screens, from immersive retail façades to mission-critical control rooms. LEDs deliver brightness, color fidelity, and dynamic content with remarkable efficiency. Yet, behind the pixels, there is one underlying decision that quietly shapes the entire life cycle of your screen: how you will maintain it.

While specifications like pixel pitch, brightness, and refresh rate tend to dominate selection conversations, the maintenance method is just as important: front service or rear service. It will define where you can physically install a screen, how quickly you can resolve faults, how much structural space you must devote, how your team will work safely, and, ultimately, what your TCO will be over years of operation.

Generally speaking, for the maintenance of LED screens, there exist mainly two popular methods: front service and rear service.

What is front service?

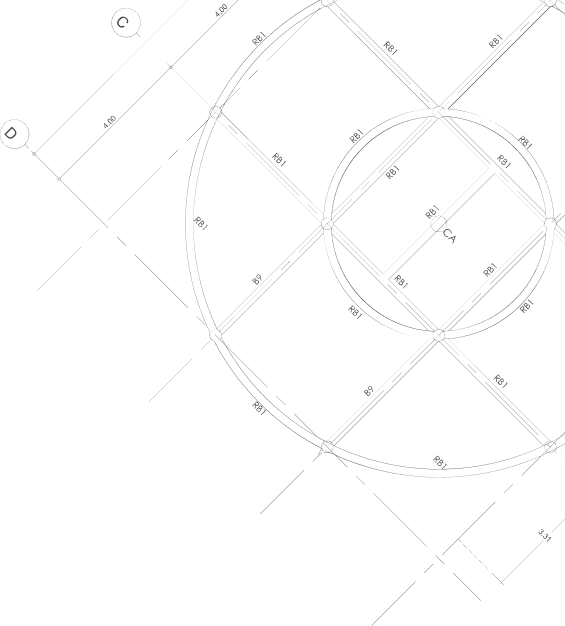

Front service is a single and direct maintenance method, engineered for environments where space behind the LED display is limited or entirely unavailable. With front service, technicians perform all maintenance actions—module replacement, power and signal access, and fine adjustments—from the front of the screen.

At present, the ways to achieve front service mainly include using magnetic mounting screws or front fixed screws (mainly for outdoor screens).

1. Magnetic Mounting Screws

This is the most common method for indoor LED displays. The core enabler is a magnetic mounting system: Each module has strong magnets to attach it magnetically to cabinet structures and typically includes a mechanical lock or “anti-drop” feature against detachment by accident. This allows for quick installations with modules being held securely but enables the removal of a single faulty module for service without access to the back.

Think of front service like replacing a tile on a finished mosaic without removing the wall. You use a specialized suction tool to lift the single tile (module) straight out from the front, swap it, and set it back into the exact place—no need to get behind the wall.

The magnetic design allows for quick and easy removal, while modules snap back into place with little effort to ensure installation remains flat and precise.

2. Front Fixed Screws With Rotary Wrench

Service at the front for larger and more robust outdoor LED screens is normally performed through front fixed screws combined with a rotary wrench.

Here, each module is screwed on from the front by special screws that can be removed with a rotary wrench. Such a design will keep every module secure and firm, even in unfavorable weather conditions.

If maintenance is needed, a technician accesses the screws from the front, loosens them with the rotary wrench, and removes the faulty module for repair or replacement. This approach provides extra security and stability for outdoor scenarios where the display faces wind, vibration, or other environmental stress.

Both of the front service methods eliminate the need for rear access, offering efficient maintenance with minimal disruption and opening up new possibilities for where and how you install your LED display.

Where front service fits best:

Tight, wall-flush installations–e.g. TV Studio, churchs, hotel and retail feature walls.

Applications that are recessed or embedded, such as glass curtain walls, with impossible back access.

Complicated forms-curves, cylinders, or any customized integrations into architecture-where the “reverse” side is unavailable or does not exist in a useful manner.

Areas where the focus is on visual integration or architectural cleanliness, and a back maintenance room or corridor opening would disturb that.

In short, front service is the solution when the screen has to be up close and personal with the built environment and back access just isn’t practical, and every millimeter in depth counts.

What is Rear Service? Rear service is a traditional approach to LED maintenance.

The design assumes that technicians will access and service the screen from behind, and this needs a dedicated maintenance corridor or backstage large enough for safe movement and work.

A typical rear clearance is on the order of 60-80 cm-or more-depending upon the structure and local safety practices.

Technicians enter this space to unbolt and remove modules, power supplies, or receiving cards from the rear of cabinets. Cabinets are mechanically fastened—by means of screws or bolts—onto sturdy steel frames designed to support weight, wind loads if outdoors, and long-term structural stability.

Where rear service fits best:

Large outdoor billboards and rooftops with dedicated steel structures with safe back access.

Control centers, broadcast walls, and facilities that can provision a planned maintenance corridor.

Indoor installations where architectural space is ample enough for a rear room or aisle that can be safely used.

If architectural space allows and if the proven stability and familiarity of traditional installations are desired, rear service often remains the logical and cost-effective choice.

The Difference Between Front Service and Rear Service

Here’s a detailed comparison that pinpoints the main differences.

Feature Front Service Rear Service

Maintenance Direction From the front of the display From behind the display

Space Required No rear space needed; can be wall-mounted Requires rear access/corridor for maintenance

Typical Application Indoor, wall installation, unique shape installations Outdoor giant screens, rear access rooms

Module Removal Method\tMagnetic mounting screws or front fixed screws with rotary wrench\tUnscrew modules from the back using traditional screws/bolts

Installation Complexityušually simpler; modules accessible directly Structure and corridor planning required

Aesthetic Integration Allows for flush or embedded installations Usually requires visible frame or access space

Speed of Maintenance Quick; front suction tools, rotary wrench Slower; more steps towards faulty modules

Cost Slightly higher because of specialty components Often lower product cost, higher structure cost

Suitability Best for locations of limited or no rear access Ideal where rear access is feasible and safe

Environmental Security Magnetic/locking system, front screws (outdoor) Traditional bolts, more robust against tampering

Heat Dissipation Needs careful design for airflow (wall flush) Easier rear ventilation management

Advantages and Disadvantages of Front Service and Rear Service

Pros and Cons of Front Service

Pros Cons

Allows maintenance from the front – no rear access needed. Usually higher initial product cost because of special design.

Ideal for wall-mounted, embedded, or tight spaces Magnetic modules may be less robust against vibration indoors only

Faster and easier module replacement; less downtime. Precision installation needed to ensure flat, seamless surface

Allows for creative shapes and flush installations. Heat dissipation needs to be carefully designed in wall-flush installs.

Less damage to building structure or existing design. For outdoor: Installing/removing front screws can be slower.

Normally requires only a single technician to change out module(s) Special tools needed-suction cup, rotary wrench

Advantages and Disadvantages of Rear Service

Pros Cons

Heavy-duty structure, strong stability-better wind/vibration resistance. Maintenance corridor/space behind the screen required

More cost-effective product and cabinet for large/outdoor screens Not suitable for wall-flush or tight installations

Traditional screw/bolt fixing is secure and familiar Module replacement takes more time and labor

Excellent heat dissipation via rear ventilation Maintenance may cause disruptions backstage

Easier to manage and maintain large-screen or outdoor LED screens; multiple technicians may be needed to work safely behind the screen.

Simpler structure for robust environments �Access is more difficult for creative shapes or designs

How to Choose the Right Maintenance Method for Your LED Display

Now, we have learned the pros and cons of front service and rear service. You might wonder: how to choose the right one for my next LED display?

Use this simple decision path to narrow your choice quickly:

1. Do you have usable rear space?

If “no,” select front service. The lack of a safe, accessible corridor essentially demands it.

If “yes,” both options remain viable; proceed to functional priorities.

2. What is most important to you in your surroundings?

Maximum structural stability and lowest initial product cost: Rear service is especially favored in large outdoor or industrial contexts.

Minimum down time and ease in serviceability: prefer front service; one-person module swaps from the front can be decisive operational advantage.

Architectural integration and aesthetics: Front service is preferred for wall-flush, recessed, or creative shapes.

2. Budget alignment

Front service typically carries a 5-10% product premium. If your budget is tight and space permits, rear service can free funds for pixel pitch, content systems, or other value-adds.

If lifecycle costs and operational continuity are the key drivers, front service can offset its premium through lower maintenance labor and reduced disruption over 5–8 years.

Scenario-based guidance:

Retail flagships and hospitality lobbies: Front service-space is at a premium, and aesthetics drive value.

Control rooms and broadcast walls: Either can work; if a rear corridor is planned, rear service is viable; if fast front access and minimum disruption are what matter most, front service is attractive.

DOOH billboards and rooftops: Rear service—robust structures, proven stability, and easy airflow usually win. Creative shapes (cylinders, curves, spheres, cubes, embedded façades): Front service—front access is usually the sole practical approach Conclusion In this article, we explored the difference between front service and rear service for LED displays via their core concepts and features. We demonstrated how it is the space constraint, maintenance speed, aesthetic, and long-term operation that shape choices more than any single spec number. We compared their advantages and disadvantages, pointing out where each one thrives, and provided guidance on how to choose to minimize risks and guesswork. If you still have questions, would like help applying this framework to your site specifically, or if you’d like a comprehensive analysis, just contact us. We’ll help you match the right maintenance approach to your environment so your LED display delivers the performance, reliability, and visual impact you expect-on day one and for years to come.